ENVIRONMENT

CRYO TECHNOLOGY FOR VOC RECOVERY

Our CRYO-PLANT is a safe, clean, reliable and efficient recovery system to control the air emissions of:

- VOCs (Volatile Organic Compounds) Methanol, Ethanol, Ethyl Acetate, Pentane, Hexane, THF, Acetonitrile,

- Aromatic solvents (Benzen,toluene), etc

- HAPs and TAPs (Hazardous or Toxic Air Pollutants) Dichloromethane, Chloroform, Vinyl Acetate

- ODSs (Ozone Depleting Substances) R11, R12, R22

Markets served:

- Chemical and Pharmaceutical

- Refrigerant Recycling

- Solvent Recycling Industry

- Organic Liquids Distribution Terminals

- Paint Industry

- Storage tank yard

- Petrochemicals

- Textile coated production farm

- And many others

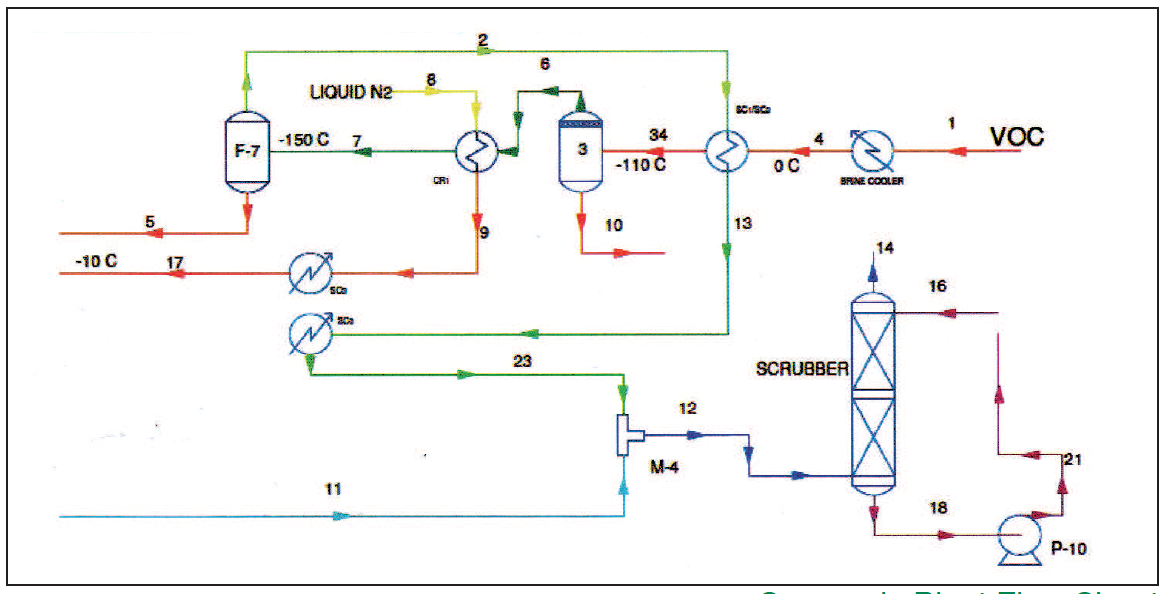

Cryogenic Plant Flow Sheet Overall: the Cryo process uses liquid nitrogen in a proprietary low temperature condenser to treat VOC laden emission streams effectively and reliably.

Pre-cooling: the VOC gas stream is first pre-cooled with available cooling fluids or a mechanical-chiller to condense the bulk of the VOCs and moisture.

Energy recovery: cold exhaust streams from the low temperature condenser are used to further pre-cool the incoming VOC gas stream.

Cryogenic condensation: the flow rate of liquid nitrogen is regulated to control the temperature of the outgoing vent gas stream from the cryo condenser. The vent gas stream with VOC has cooled down to the desired temperature to help ensure compliance.

VOC recovery: condensed VOCs pass through droplet separators and are collected in a tank to be pumped and reused.

Nitrogen recovery: liquid nitrogen is fully vaporised in the process and exits the system as clean nitrogen gas to be reused for other applications.

Features & Benefits

- Cryogenic condensation allows recovery above 99% of most VOCs

- We offer modelling and simulation software

- Non-destructive recovery: condensate can be recycled, re-sold, burned for energy content or further purified

- Recovery of halogenated compounds which may not be practical to incinerate

- Recovery of gaseous nitrogen: for inerting and blanketing applications

- Compact design: small footprint, easy to install, scale and relocate

- Tailored solutions: able to combine liquid nitrogen cooling, mechanical cooling, activated carbon and molecular sieve adsorption and acid scrubbing technologies into a single solution

- Global reach: ISO9001, PED 97/23, ASME, ATEX